Weight dosing

The weight dosing can be measured according to the weight loss, or according to the weight gained by the big bag during its emptying or filling.

More precise than volumetric dosing, weight dosing requires the installation of a weighing chain to be realized.

The weighing chain consists of :

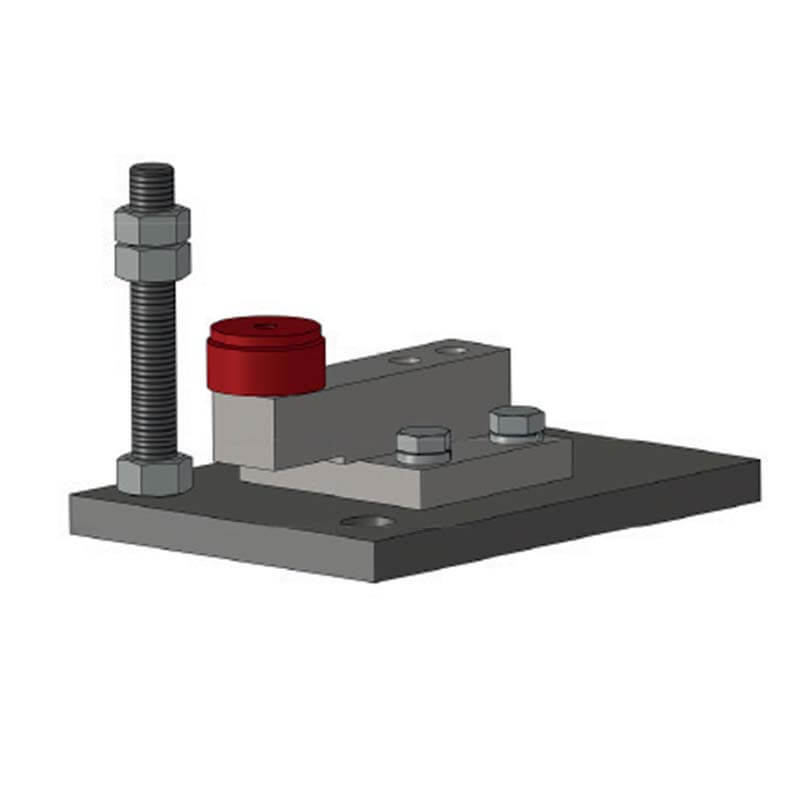

- 4 load cells located on the emptying or big bag filling station

- A connection box

- A display of the weight in kg

- An electrical cabinet with buttons on the front or with an integrated HMI acting as a control screen.

This chain can be controlled by an automaton. The role of the HMI is to send information to the automaton concerning the desired target weight. Once this target weight is reached, the machine stops.

The HMI (Human Machine Interface) integrated into our electrical cabinets has many benefits such as :

- The possibility of easy and quick control and adjustment

- Better visibility on the current operation (emptying/filling)

- increase in productivity

- automatic stop in case of anomaly (safe)

- improved ergonomics

- An HMI is integrated into the big bag emptying stations and big bag filling stations.

The programs contained in the HMI are installed by our automation specialists.

Weight dosing is also possible with a weighing hoist.

This system can give weight with commercial or non-commercial precision.