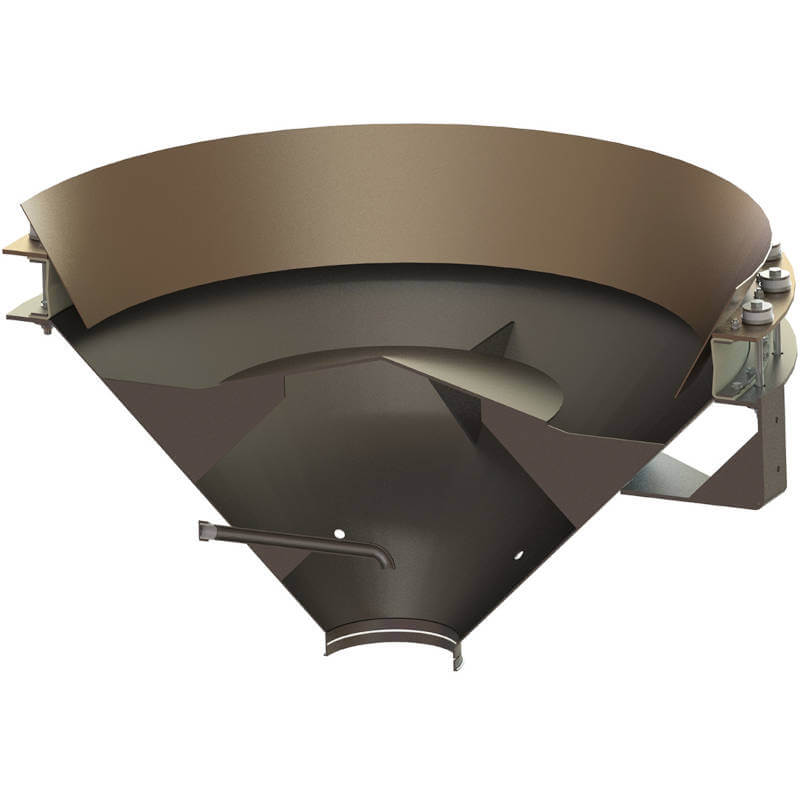

Pneumatic accelerator

Pneumatic accelerator

It is a pneumatic device intended to improve the flowability of difficult and cohesive products. It can also accelerate the emptying of products with normal flowability in case of a lack of flow.

It helps the flow of cohesive powders that tend to clog the outlet of the bin activator. Indeed, the pneumatic accelerator generates a compressed air flush towards the outlet of the bin activator. The mechanical effect of this air flush is to remove the product blocked in its area of action.

The use of a pneumatic accelerator facilitates the restart of a powder flow after a prolonged stop of the bin activator for example.