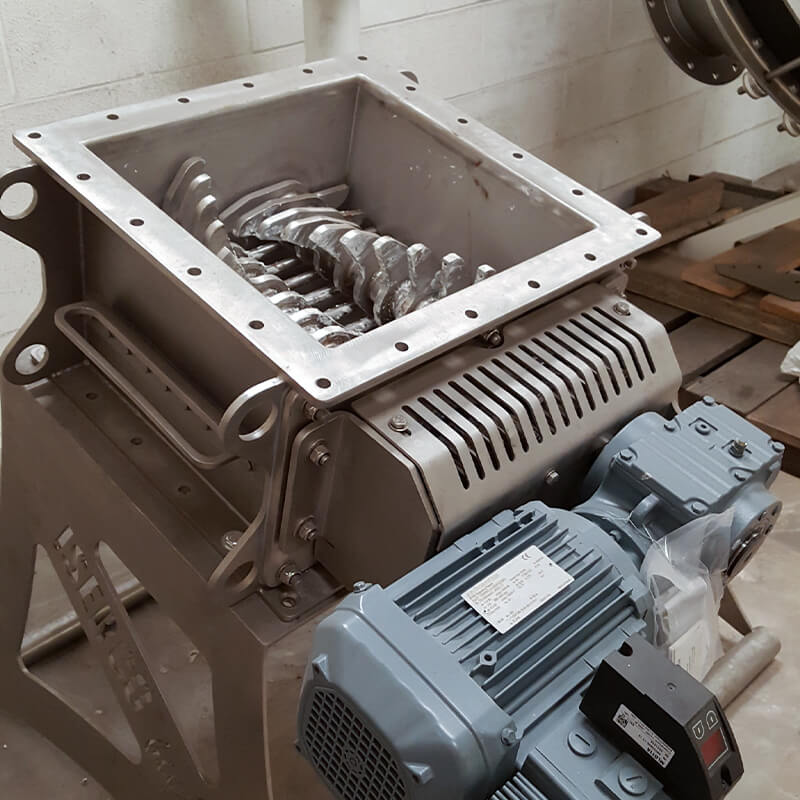

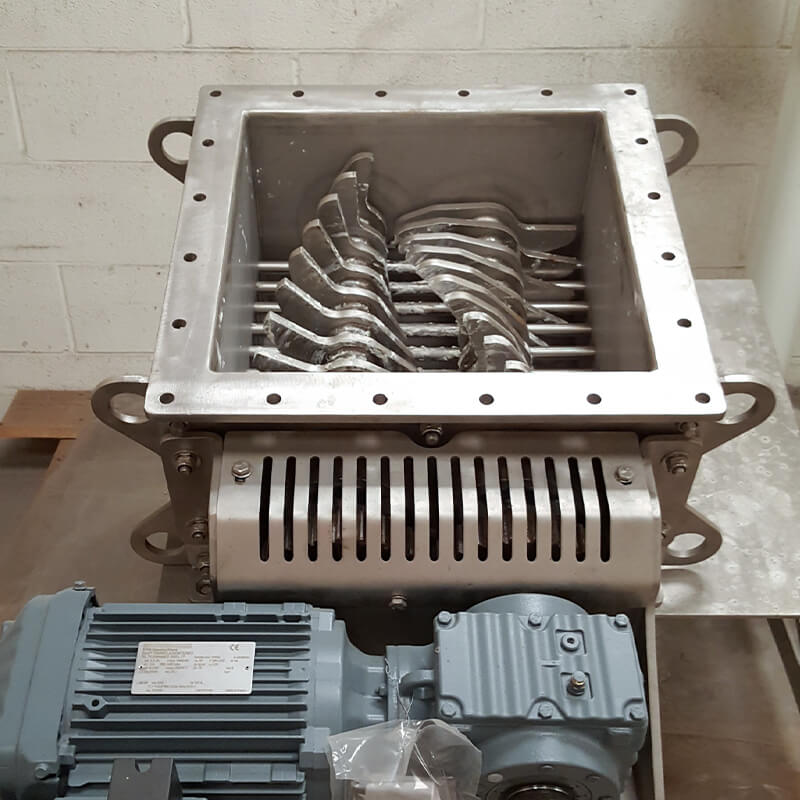

Lump-breaker with double crushing shaft

Lump-breaker with double crushing shaft

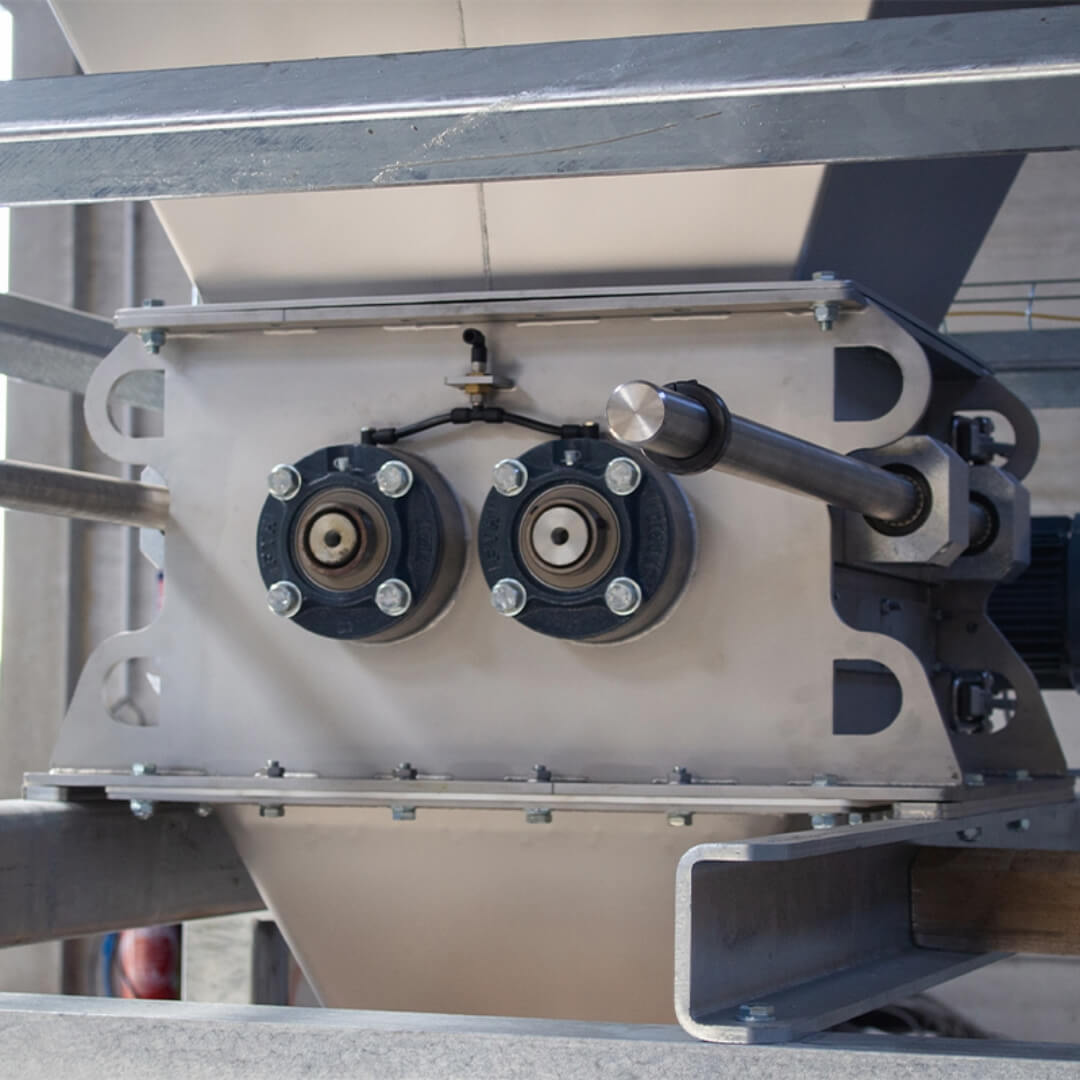

The lump breaker is an ideal solution to reduce the size grading of products tending to form lumps. Composed of a primary shaft and a secondary shaft rotating in opposite directions, this assembly allows the crushing of lumps that form during the transport of cohesive products.

It is available in different sizes, from the diameter 300 to the diameter 1000 mm and it can process a large quantity of product. The lump breaker with double crushing shaft allows flow of 40m³ of product per hour.

The lump breaker is integrated under the sealing and pre-transport system. Its limited height enables it to be easily integrated into processes where space is limited.