When it comes to non-cohesive solids, the bin activator provides the following benefits:

• A vertical space saving,

• An homogeneous extraction, approaching mass-flow

If your products are cohesive, on top of the benefits listed above, the bin

activator will:

• Avoid the creation of bridging by positioning geometrically over the theoretical construction of the latter

• Avoid the creation of chimneys by balancing the course of particle positioned in the middle or at the periphery of the silo

• Avoid collapsing by having a more symmetrical outflow

• Dissociating the frictional forces which bind the particles together, passing them from the friction state to the sliding state, the bin activator is essential when it comes to power a process (weighing, dosing, pneumatic conveying etc.)

A little bit of technique…

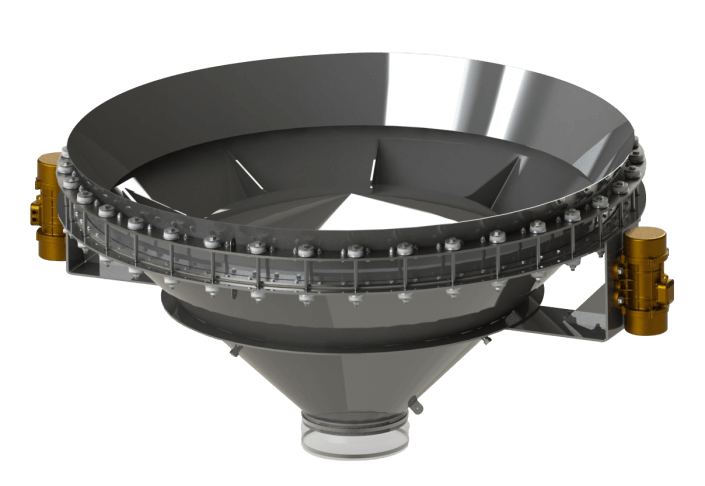

Our standard range of bin activators varies from diameter 450-4500 mm. In the same way, output diameters range from 150 to 600 mm. Different diameters on request.

- We work carbon steel and stainless steel.

- Our carbon steel bin activators are shot blast and then painted. We offer a wide range of different types of paint (choice of RAL n°, food grade paint etc.)

- Our stainless steel bin activators can be either glass bead blasted inside and outside. A wide range of polishing can be provided.

- Each bin activator design depends on the product, its environment, its storage type.

- Each bin activator is custom designed. A wide range of baffle is available (primary baffle, fluidized baffle etc.)

Our know-how enables us to manufacture a variety of special bin activators: square bin activators, bin activators in panels (adapted when their difficult installation requires) and bin activators with several outlets.