Showing 17–23 of 23 results

- Iserco

- Equipment

- Big bagYour solution for handling products in big bags Your products are conditioned in bigbags, we put at your disposal a series of equipments to fill them, to empty them, to dose your products, to transfer them to your production line, … Choose what you want to do

- Emptying a big bagYour Bulk Handling Solution Choose your product

- Filling a big bagYour Bulk Handling Solution Choose your product

- Dosing a productYour Bulk Handling Solution Choose your product

- Transfer a productYour Bulk Handling Solution Choose your product

- Reduce a productYour Bulk Handling Solution Choose your product

- Big Bag accessoriesYour Bulk Handling Solution Choose your accessories

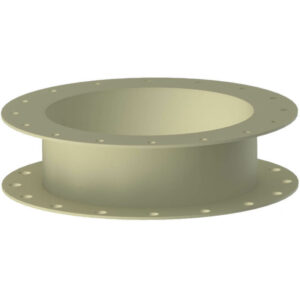

- Big Bag spare partsISERCO Spare parts for big bag The safety, reliability and longevity of an equipment are directly linked to the use of perfectly adapted parts. By choosing original ISERCO parts, you put all the chances on your side.

- BagYour solution for handling products in bags Some of your products are conditioned in bags? ISERCO offers specific solutions for this type of container. Choose what you want to do

- SiloYour solution for handling products in silos Your products are conditioned in silos, ISERCO offers a set of equipment to fill / empty your silos. Choose what you want to do

- Big bagYour solution for handling products in big bags Your products are conditioned in bigbags, we put at your disposal a series of equipments to fill them, to empty them, to dose your products, to transfer them to your production line, … Choose what you want to do

- Business Area

- Executions

- News

- Contact us